JEKON is the brand, that offers Semilift Diaphragm Low Pressure Solenoid Valve

It is suitable for Autoclaves, Gas burning equipment plants, vacuum plants, pump seal water, low-pressure water circulation system, soler heating systems, gas generators, etc.

| Specifications | Valve |

| Body Material | SS-304 / SS-316 / Brass |

| Size Range | 1/2″ to 3″ |

| Type | 2 Port, 2 Position (NC) |

| Pressure Rating | 0 to 5 bar |

| Circumference Temperature | -10 °C to 95 °C (PTFE = 150 °C) |

| Media Temperature | -10 °C to 95 °C (PTFE = 180 °C) |

| Operating Voltage | AC : 230V, 110V, 48V, 24V DC: 12V, 24V |

| Power Consumption | AC: 8W, 12W, 17W DC: 8W |

| Media | Air, Water, Steam, Gases, |

Semilift Diaphragm low pressure Solenoid Valve Manufacturer in India

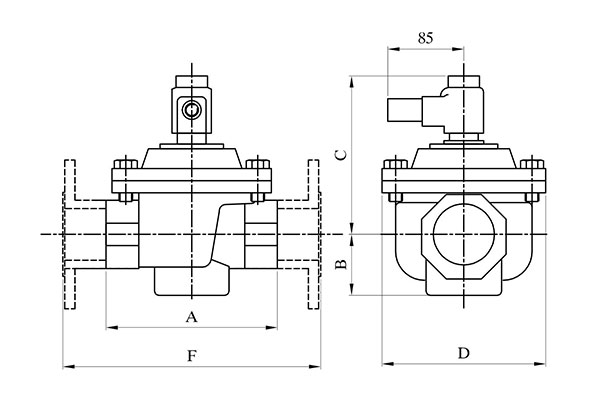

| Dimensions | |||||||

| Model | Size | A | B | C | D | F | |

| MM | Inch | ||||||

| JLSV-15 | 15 | 1/2″ | 66 | 13. 5 | 100. 5 | 57 | 130 |

| JLSV-20 | 20 | 3/4″ | 82 | 21. 0 | 115 | 68. 5 | 150 |

| JLSV-25 | 25 | 1″ | 115 | 29. 0 | 121 | 82 | 160 |

| JLSV-40 | 40 | 1.1/2″ | 119 | 35. 0 | 133 | 100 | 200 |

| JLSV-50 | 50 | 2″ | 137 | 43. 5 | 143. 5 | 120 | 230 |

| All Dimensions are in (mm.) | |||||||

Semi Lift Diaphragm Low Pressure Solenoid Valve Manufacturer

The Semilift Diaphragm Low Pressure Solenoid Valve is an efficient and reliable fluid control device that is specifically crafted to serve low-pressure applications. The semilift diaphragm design, in contrast to conventional solenoid valves, can operate smoothly even at very low inlet pressure or close to zero pressure because a minimum difference in pressure can be used to operate them. This renders them useful to utilize in systems that require precise fluid movement, but the conditions of pressure are not such that they can be utilized to actuate conventional valves. They are usually applied in the management of air, water, non-corrosive liquids, light oils, inert gases, and other fluids in industrial and commercial applications. The operating principle of a semilift diaphragm valve consists of a solenoid coil, upon which firing causes the formation of a magnetic field which upraises a pilot plunger. To a small extent, this motion causes an opening in the diaphragm, allowing the flow of fluid through the valve body even when the pressure is low. The plunger closes the pilot orifice when de-energized and the diaphragm goes back to its position, stopping the flow. These valves can be actuated with very low actuation forces due to their design, which minimizes power use and will increase service life. They are normally small, light and easy to install and so are a feasible solution to a space-constrained system. These valves enjoy great popularity in water treatment systems, low-pressure pneumatic systems, food and beverage processing, laboratory equipment and small-scale automation systems. Having the capability to function under low pressure without the need to use a minimum pressure difference would guarantee them stable performance in intermittent flow operation or gravity-fed-oriented systems. Moreover, numerous semilift diaphragm solenoid valves are produced in non-corrosive materials like brass or stainless steel and are therefore durable and can last a long time. All in all, they provide an affordable and reliable answer to low-pressure fluid control requirements; accuracy, safety and energy efficiency in one small package.