| Part Name | Actuator |

| Body | SS 304 Pressed |

| Size Range | 1/2″ To 2″ |

| Cover Flange | ASTM A351 Gr. Cf8 (SS 304) Investment Die-Cast |

| Spring | Spring Steel (IS 4454 Gr. III) |

| Port Connection | 1/4″ BSP (NPT on request) |

| Operating Pressure | 3.5 to 7 Bar |

| Position Indicator | Nylon |

| Operating Cycles | 350 to 650 Cycles / Hr. |

| Media | Dry Lubricated Air / Inert Gasses Jekon Moisture Separators are advised to use inline |

| Specification | Valve |

| Size | 1/2″ to 3″ Flanged |

| Body | ASTM A351 Gr. CF8 / CF8M / CF3M |

| Steam Packing | PTFE upto 180°C, Self-compensating (Spring Loaded) |

| Trim / Spindle | Stainless Steel 304/316/316L |

| Seat | Soft Seat (PTFE) |

| Gland Packing | Teflon ‘V’ seals, backed by graphite wiper seal (Self Compensating) |

| Body Test Pressure | 42 Bar Maximum |

| End Connections | Flanged End |

| Working Fluid Press | Drop tight / bubble tight, class IV ANSI B 16, 104, 1976 |

| Leakage | On steam – Continues 155°C, Intermittent 180°C Maximum |

| Operating Temp. | (High Temp. above 180°C – On Request) |

| Media | Air, Water, Oil, Gas, Steam & Chemical |

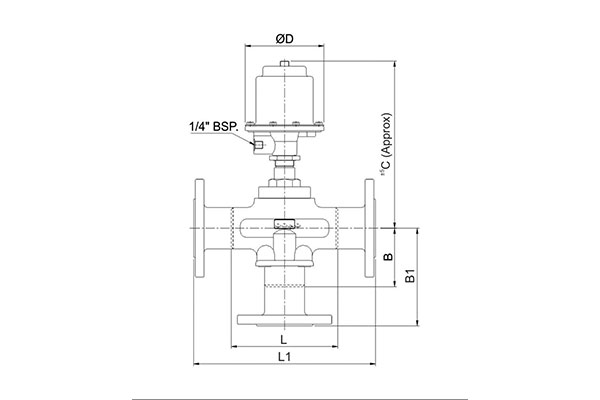

| Dimensions | ||||||||

Valve Type | Size | L | L1 | B | B1 | C | D | |

| MM | In. | |||||||

| J3V-F-15 | 15 | 1/2″ | 85 | 151 | 50 | 83 | 185 | 102 |

| J3V-F-20 | 20 | 3/4″ | 110 | 185 | 66 | 130.5 | 194 | 102 |

| J3V-F-25 | 25 | 1″ | 120 | 189 | 72 | 106.5 | 204 | 102 |

| J3V-F-40 | 40 | 1-1/2″ | 150 | 232 | 91 | 132 | 285 | 134 |

| J3V-F-50 | 50 | 2″ | 190 | 283 | 100 | 146.5 | 292 | 164 |